Ultramarine is a blue pigment consisting primarily of a zeolite-based mineral containing small amounts of polysulphides. It occurs in nature as a proximate component of lapis lazuli. The pigment color code is P. Blue 29 77007. Ultramarine is the most complex of the mineral pigments, a complex sulphur-containing sodio-silicate (Na8-10Al6Si6O24S2-4) containing a blue cubic mineral called lazurite (the major component in lapis lazuli). Some chloride is often present in the crystal lattice as well. The blue color of the pigment is due to the S3− radical anion, which contains an unpaired electron.

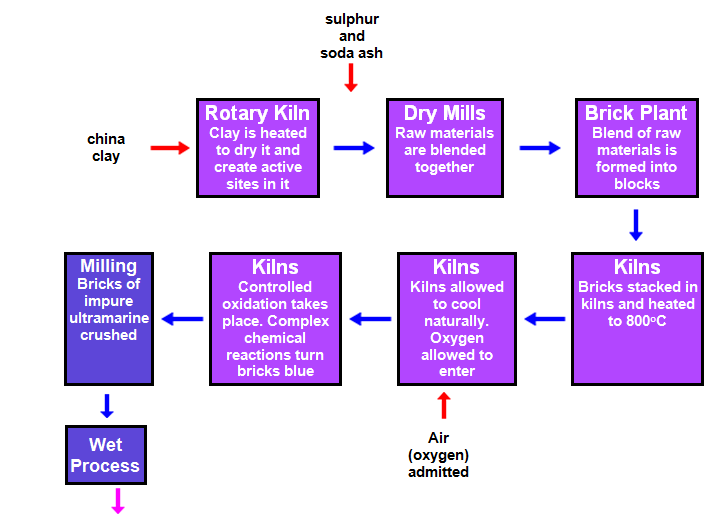

The raw materials used in the manufacture are: (1) iron-free kaolin, or some other kind of pure clay, which should contain its silica and alumina as nearly as possible in the proportion of SiO2:Al2O3 demanded by the formula assigned to ideal kaolin (a deficit of silica, however, it appears can be made up for by addition of the calculated weight of finely divided silica); (2) anhydrous Na2SO4; (3) anhydrous Na2CO3; (4) powdered sulphur; and (5) powdered charcoal or relatively ash-free coal, or colophony in lumps.

The mixture is heated in a kiln, sometimes in brick-sized amounts. The resultant solids are then ground and washed as per any other insoluble pigment manufacturing process.

ULTRAMARINE MANUFACTURE : THE DRY PROCESS

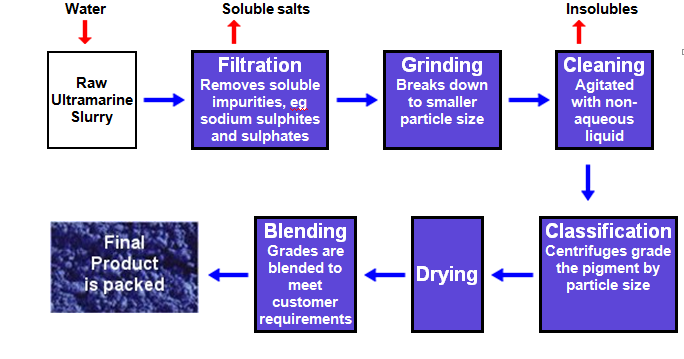

ULTRAMARINE MANUFACTURE : THE WET PROCESS